Thing is, the PL-13 is especially designed to fit underneath the PL-10 engine. The beam from the motor fits through a hole on the PL-13 and synchronizes it's movement with the point current position.

It doesn't have to be motorised. (Actually, I simply hate those peco vertical motors). Neither must you change the turnout wiring. Any setup that you might come up with will do the trick. As long as that wire that is connected to the underside of the turnout is connected to the proper rail for every position of the turnout.

Here's an example of someone with your exact problem:

Check this guy's blog:

Stazione di Cretaz

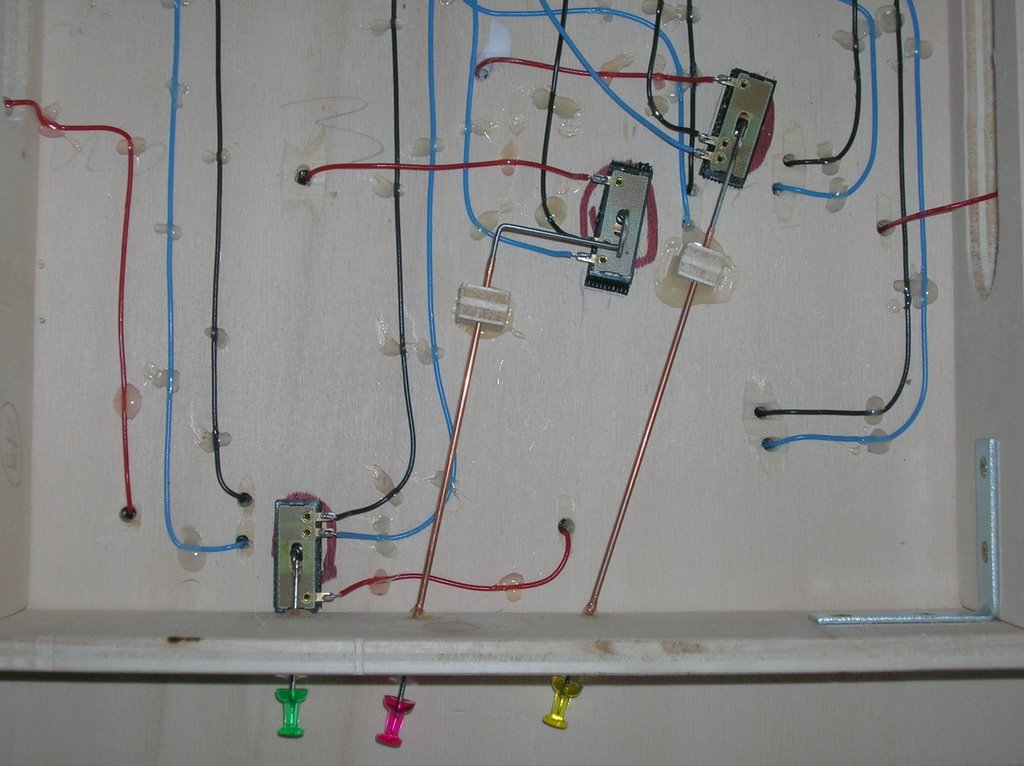

In this picture:

The guy used a small beam which he uses to manually change the turnout. That beam changes the PL-13 and the turnout at the same time.

Cheers

QUOTE (sennapod @ 13 Oct 2010, 15:44)

<{POST_SNAPBACK}>This is also a topic that interests me - I'm also new to Electrofrog and want the benefits - especially of short wheelbase locos not stalling on the frog (as they do on Insulfrog).

although this thread has been dormant for a while - I hope someone can still help...

The feedback given (especially by Taigo on 19/Aug) is that Peco recommend a PL-13 switch which has to be fitted under a point motor - meaning the entire point must be motorised (kinda obvious statement I know...

)

My question is simply - does it have to be motorised? As PL13 usage seems synonymous with a point-motor, is there an equivalent manual solution (which I guess would require some adaptation of the wiring mandated by Peco on their turnout leaflet and perhaps a different switch model. Or would I then have to physically move the points AND flick the switch to reverse frog-polarity, at the same time.?

Or is there any completely alternate way of wiring Electroforgs for DCC. I've looked at Brian Lamberts site - although I've relied on it in the past for other things - on this topic I don't really get it.

![Image]()